not only is this the hottest interior magazine in the game,

the staff & writers are super nice.

so flattered to be on their pages.

Mahima Singh

I had the honor and privilege to interview Mahima Singh for Ceramics Monthly's March issue. We overlapped at Pottery Northwest, she helped me setup my first* studio at EQuinox and she has impressed, surprised and humbled me, every.step.of.the.way. I have never met someone as thoughtful and wise as Mahima, who manages to live with so much joy at the same time. Follow her on instagram if you don't already - her images exude sunshine and freshness. @clayisokay

With their permison here's the article in full: originally published in March 2017 issue of Ceramics Monthly, pages 50,51,52. http://www.ceramicsmonthly.org . Copyright, The American Ceramic Society. Reprinted with permission.

ps

*oooh! Did I say "first"?! That's a hint... x

happy holidaze

Wishing you and your families all the the best for the holidays and the New Year.

Thank you for everyone who is gifting my work this year

your support and belief in my work feels amazing

and I appreciate it more than I can say.

To everyone receiving something this year,

I hope you enjoy your goodies.

with love,

xSarah

last show of 2016

Do come down to Magnuson Park, Hanger 30

this weekend and finish up your Christmas shopping

with me and the other 150 makers

sharing their creative work.

xxSarah

busy as a bee

November Ceramics Monthly

Here's the article I wrote for this month's for Ceramics Monthly. I very much appreciative their support and interest in my story, and I hope you enjoy reading it here, republished with their permission.

For those of you paying close attention, the dog in the picture is Shelby, not Jones. Shelby is my "dog-daughter" a blond lab, and when her Dad used to travel for work she'd be with me in the studio. A few months before we got Jones, Shelby's Dad started traveling less, and so we made room for my new studio pup Jones. If you want to see him at work in the studio have a look here on instagram.

enjoy xx

ps

the title makes me a little uncomfortable,

I'm still very much me,

my job just changed a little.

Originally published in November 2016 issue of Ceramics Monthly, pages 36-39. http://www.ceramicsmonthly.org . Copyright, The American Ceramic Society. Reprinted with permission.

Equinox Open House - Second Saturday

Every Second Saturday of the month, Equinox's makers open their doors from 6-9pm for the public to come and adventure in art land. It's a different mix of makers every month, but always an adventure with fire pits in the street, and music and creativity pouring out the doors.

You can also follow Equinox on facebook here - and they make an event every month and share who will be open, which is a nice way to follow a wider maker community.

Last month, I asked for visitors input on some nesting bowls I was developing, and this time I have new porcelain earrings* on offer (warning, these will ruin you for other earrings, they are so light). Usually, I've a few samples and seconds on sale alongside my own work - so bargain hunter be ready...

Stop by, and say hi - and give Jones a scratch under his chin he loves visitors!

6560 5th Ave S. Equinox Studios, The LivingRoom Bldg, Seattle, WA 98108

(it's the single metal door, opposite the picnic table and basketball hoop)

that's my bowl, in the Seattle Times.

Super flattered that one of my bowls made in onto this list, thank you Seattle Times. Bonus that my good friend Andrea Ramsey is in the feature too. #stripes

Today was a good day.

Thank you Seattle Times, Caitlin King, and the Universe.

xx

Saturday August 6th, do come and say hi

Spotlight

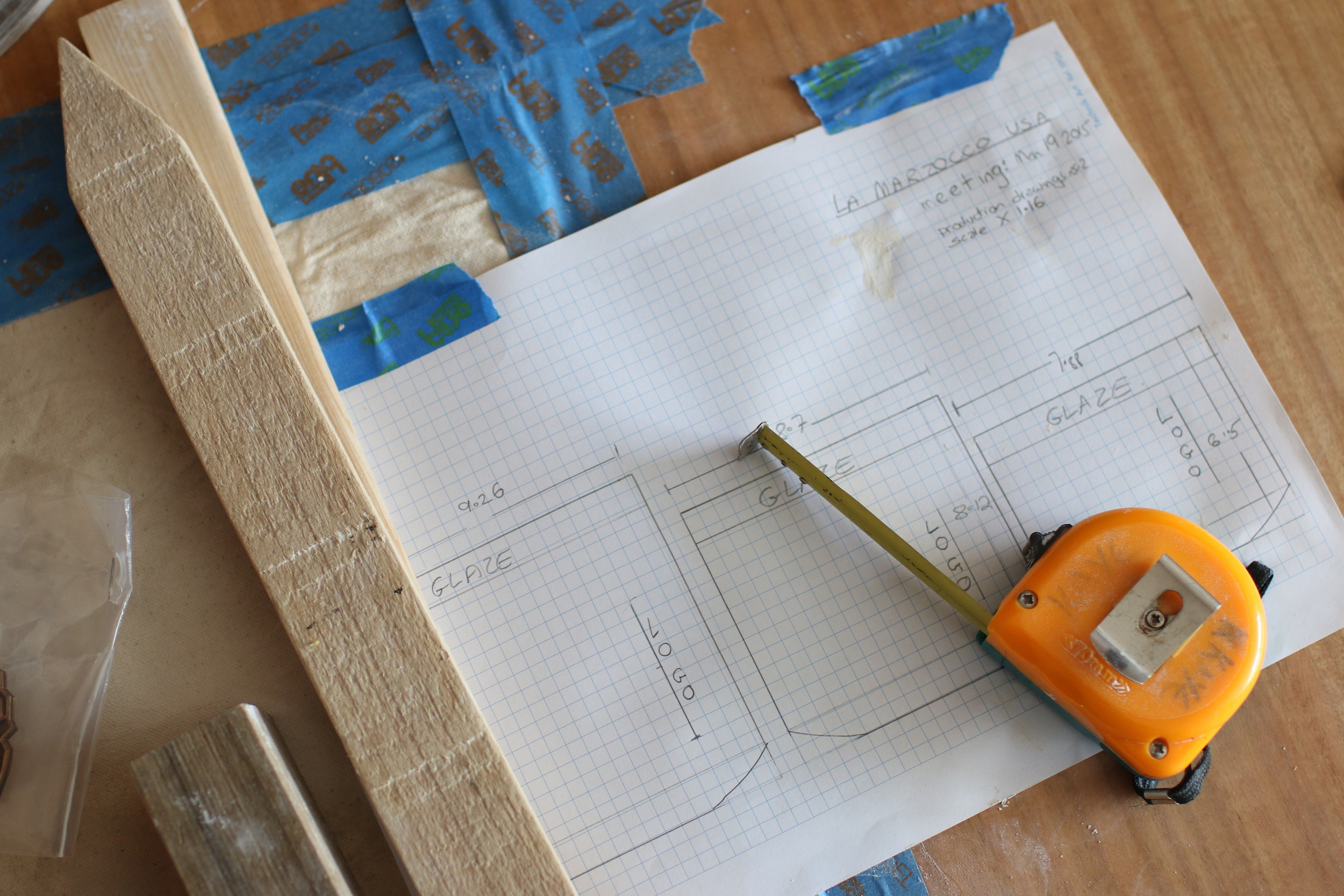

This Spotlight article was published in the February issue of Ceramics Monthly about little ol' me (!) and my collaboration with La Marzocco Home. Thank you to Marcie McCabe (PR to Pottery Northwest) for the introduction, & thank you to Jessica Knapp (editor, Ceramics Monthly) for your interest in the project and your guidance.

My brother & I grew up on two sides of the product design field - he is in tech, and I was the physical design stuff. We made a deal many moons ago that whichever of us made it into I.D. Magazine first, the other would buy them dinner at a restaurant of their choice.

@Jofish - this isn't I.D. Magazine -- but it IS a full page spread.

Do you want to settle up?

Lastly, a grateful shout out to Kelly Ballantyne photographer extraordinaire, who made me smile, and managed a number of nice photographs of me in the studio that day. (This is no easy task, I grimace almost involuntarily at cameras.) I highly recommend her for ambiance portrait work - look how warm and inviting this photo is.

CLICK TO ENLARGE PHOTO & TEXT

Originally published in the February 2016 issue of Ceramics Monthly, page (80).

http://www.ceramicsmonthly.org

Copyright, The American Ceramic Society. Reprinted with permission."

La Marzocco Home

The day after I signed for the keys to my studio at Equinox I took a call with Scott Callander at La Marzocco Home who was looking to source custom cups to be sold as accompaniments to their home espresso machines. He asked when they could visit my studio to talk in detail about the designs they were looking for, and I suggested Friday… giving me just enough time to sort the studio out, unpack boxes and build a few IKEA Omar shelves.

When we met we hit if off right away, and afterwards I sent Scott along with a few schematic drawings and a note saying, “it was great to hang out”. We went back and forth tweaking the design and having agreed on form, tone of grey, size of logo and glaze application – it was go time.

The La Marzocco cups have flown off the shelves with help from their great marketing team. The cups were even the lead gift item in this article on Sprudge:

Working with La Marzocco has been a gift. My lead client Scott, has been client, friend and mentor as my fledgling business is stepping up to the plate with a company well versed in supply, production and design quality. They are also well versed in social media and content production and Ben Blaze, creative & photographer extraordinaire, spent a few days at my studio documenting my process. He generously shared his photos from that time with me, here's a peak for you.

and a tinny peak at some of their press photos, but for full effect see their Instagram

up your game

As I mentioned I will continue to teach at Pottery Northwest and I'm starting to understand how things work there. Residents get to propose their own classes and we've had coffee focused class, and another that had beer brewing as a focus - so there's lots scope to play with. After 2 years of watching some really talented people not giving themselves the permission to take their clay practice seriously - I wanted a class that had the structure I could really push my students with. The class I proposed and taught this time was called “up your game”.

I was lucky to have a great mix of students old and new and they all took the challenge of the class seriously. They set themselves goals at the beginning of the semester and smashed past them, challenging themselves to try new things and put a little more effort and consideration into their work.

It was really fun to teach the class and have the freedom to be ‘tough,’ calling my students out when they were cutting corners. As a bonus trickle on effect, while I always try to ‘up my game’ in my personal practice – teaching this class made me more aware in my own studio too.

I am very proud. I only spent 3-4 hours a week with these projects, but at the end of 10 weeks – it feels almost as good as if they were my own. I’m reminded it’s a real honor to teach. Here are a few pictures of their work.

a new home for my studio in Georgetown

After my exit show at Pottery Northwest I had to move out, (as the residency is only for 2 years). They have a lovely way of putting it, which is: it's not The End, we are just changing our relationship -- I will continue to teach there and be a part of the community.

As a new home, I found myself a 300 square foot studio space at Georgetown’s Equinox Studios. EQ is bubbling over with creative people from blacksmiths and painters, to installation artists, costumers and a few clay folks too. It is a really friendly, warm community and there's always something bizarre happening. From forklift acrobatics, to three wheel trikes popping wheelies outside my window -- there's always a distraction. My first day in the studio I saw someone showing up at 5:25pm on a Tuesday afternoon, riding one of the community BMX with a fresh growler fill for the evening. It was then, that I was certain I knew I was going to like it here.

If you are curious to know more, here’s a little thirty minute segment that aired on local TV just weeks after I moved in. You can see my hands at work about 2 minutes in, and there are a few ambiance shots of my studio space towards the end too.

http://www.seattlechannel.org/artZone/?videoid=x60103

Queen Anne and Magnolia News

so this happened,

(and mum was proud)

click the image to see the whole article

Actually, as this is my blog, I think I can take a moment to muse on the article. This was my first time dealing with the press about my own work. While it's a wholly a positive article, and lots of QA & MN readers visited the gallery and saw my show - it is not entirely how I would have told the story. There's something grating about the quote that my husband told me to get out the house -- out of the context of the conversation, it sounds less playful than how the story was told, and brushes my feminist sensibilities. But, "if there's no such thing as bad press" -- then hoorah!

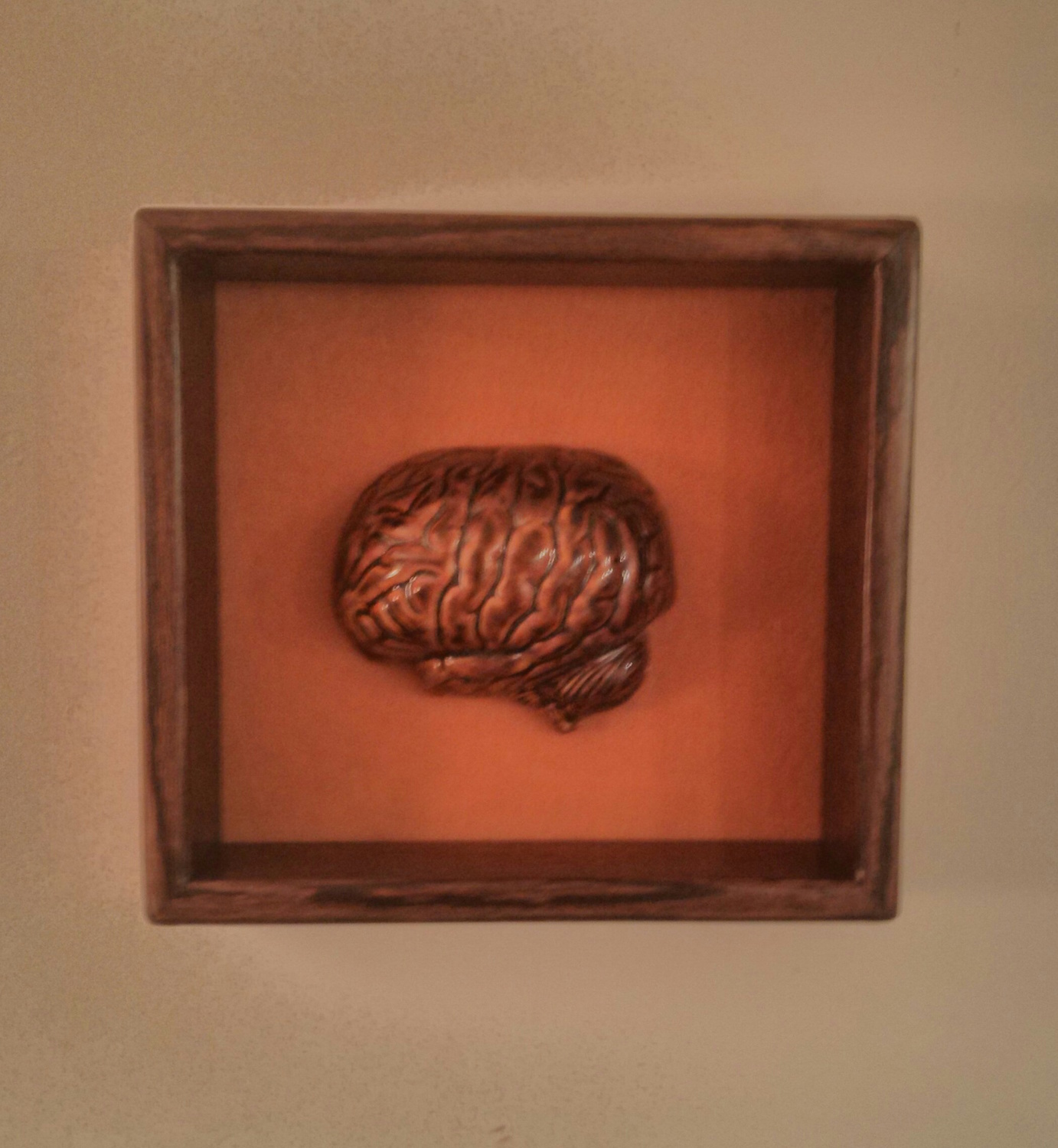

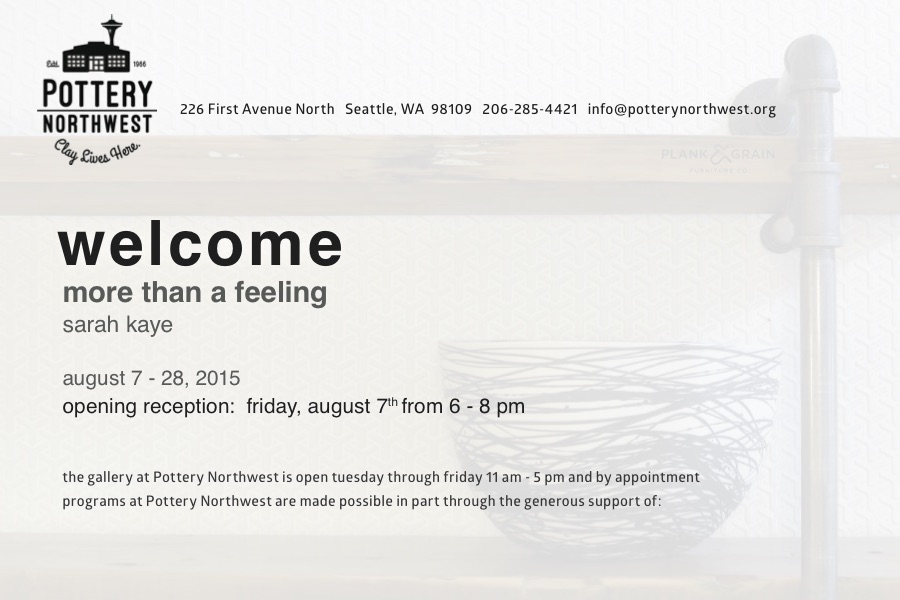

welcome - more thank a feeling

Friday evening was the opening night of my exit show

celebrating two years as a resident at Pottery Northwest.

Below are some photos from the night of the opening.

If you missed the opening, and would like a guided tour

please do drop me a line - and I will happily meet you at the gallery to talk about the work.

The show is up until the end of August.

This started as a thank you to my photographers,

and it grew and grew,

as there are so many people that supported me to this point.

Thank you to Sudhi Tirnahalli and Robert Alexander

for being my photographers so I could focus on other things.

(like hugging guests and directing them towards the beer and bubbles!)

to Jane Hill, transatlantic DJ.

to Plank & Grain, for the generous loan of their handmade, furniture.

Their custom furniture is lovingly made from reclaimed wood

found in old buildings around the Pacific Northwest.

Their work is exquisite and affordable

and I can't count the number of people who have raved about it to me since the show went up.

(and to Jordan, who introduced me to Plank & Grain, I consider my creative fairy godmother.)

James Lobb director of Pottery Northwest, who truly enjoys facilitating artists making and showing their art.

Only surpassed by his wife Brooke - who is the calm presence at each of our openings - and the person who makes everything alright on the night. They both follow elegantly in the footsteps of Wally & Julie Bivins who lead the way before them. Also, thank you to Wally for taking a chance on me, and all of your guidance, and friendship.

Robert, Mum, Dad, Joe, Helene & Wolfe, Alex & Eileen, Bridget, Margaret & Chris, Janie, Ra&G, Vicky, Mel, Noriko, Momo, and all my friends and family who have believed in me, supporting my clay career from way back when - and patiently waited while I found my way back here.

I could go on... it takes a village.

Also, thank you to The Village.

celebrating two years at pottery northwest

I have my exit show at Pottery Northwest next week,

celebrating my 2 years as a resident.

If you are in Seattle, you should come join us...

and now - back to work!

I'll tell you more after the 7th.

I had an email yesterday with an inquiry about working together

(fingers crossed, this could be a really exciting project...)

from someone who saw this photo on instagram.

Thank you Sprudge for the feature

and The London Plane for carrying my work in the first place

and my brilliant friend Jordan for the introduction to TLP.

Also their post is timely!

As I have to say with the warm weather coming in,

these cups are coming into their peak season

they are called: Gin and Tonic Please!

thank you universe. xx

synesso

In early February I had an e-mail via this website from Katy at Synesso a company that hand-builds high end espresso machines in Georgetown (Seattle).

I knew of their machines from living in Melbourne, (shout out to Proud Mary!) In Auz - people cared about their coffee in way I've never seen anywhere else. Kit matters... I learnt that if you were grinding your beans in anything other than a conical burr grinder you might as well, not. So you got to knowing about the machines that made good coffee and Synesso was top of the list.

They were looking for espresso cups, to give as thank you gifts to dealers to commemorate their first ten years in business. Specifically they wanted cups with a "clean aesthetic to parallel the precision in what we do." Which, is a compliment but also - scary, as it can be tough to get clay too 'precise' since its organic (and sometimes, temperamental!) but up for the challenge Katy, Sandy and I started designing together.

Synesso had a few samples, one from a quite well known maker in California and I think the other was an East Coaster... they liked both designs - but really wanted someone local to make the cups. I met them with a few samples of my own - riffing off what they'd shared -- we played around making coffees in them, and seeing what worked and what didn't.

The big thing we changed from my starting point was to round the inside of the cup. I've been working with sharper corners in my work -- which is a tell to my production method... but to get the most from your espresso you want to allow the crema to land gently and flow uninterrupted so it can maintain its texture, heat and bloom. So rounded it was... we tried a few shapes (see the inverted versions on the right) and looked at how they sat... on a table, in your hand, and still rounded itself on the inside.

We could have kept the squared off exterior and then - using a two part mold - had a rounded inside. For two reasons this didn't appeal: foremost, I like the integrity or honesty of a one part mold - it looks like what it is, simple and straightforward. Secondly, we had a month to produce these cups, and I didn't want the additional time spent front end tooling a two part mold (and additional costs to the client) which would slow things down.

I also made the cups really thick for Synesso. I mentioned earlier that clay is organic and sometimes (gasp!) temperamental... half way through an easy day of casting my molds will do strange things (see picture on the left).

Which has to do with the clay having an upset feeling... (Actually its more technical than that - as far as I understand its a flocculation issue ((which does come from overuse / neglect)) - maybe a post of this later for the clay nerds.) My point is, sometimes clay is hard to predict and control, so when Katy and Sandy casually wielded digital caliper to talk about size and thickness... I was a little nervous. Our aim was to produce a cup that didn't need a saucer, and could be handled hot off the machine with no discomfort which we got to. But I was very aware that makers of precision coffee machines weren't going to thrilled with an ish. Shout out to Alexa, my virtual assistant "Alexa, set a timer for 24 minutes," who kept the cups coming out an even thickness.

Another thing we looked at was surface decoration -- initially we were playing with idea of a silver markings on the cups reflecting the silver detailing on the Synesso machines -- but a little research turned up that they would require hand washing and even then the silver would eventually fade. Not being durable was a big no no for all of us. We wanted our design to last, and last well. So we chose to use red slip -- and like my normal production method make it integral to the cup surface. It will never wash off, never fade... you can't even scratch it (unlike a glazed surface.)

I set about honing my red slip... to match Synesso's red branding. Testing two different mason stains at different concentrations in order to get a red that really pops. The photos below are the raw red stain mixed in water, the stain mixed with slip and the the first round of test colours. We went a second round, as we were looking for something really punch. In the end our concentration was at 15% stain to slip which is really high! (don't tell my students, I don't let them mix slip above 4%) The middle photo I think of as 'just for me' moment... I love watching the patterns bloom before it is mixed properly and have recently experimented a little with making work this way, but I'm pretty sure I was over tie dye before I became a teenager.

The final step to resolve before I could make the molds was the logo - and I worked with metrix space using their laser cutters, laser etchers and 3D printers in order to develop the right stamp to put in the foot of the cup. Large enough for the detail to be seen, delicate enough to not distract, and tapered in a manner that the cups would release from the design easily. I thought the best tool for the job would be the 3d printer -- but the detail was too delicate for the machine. Next up was the laser cutter, but that's like using a chainsaw to julienne carrots -- and so: the laser etcher while a more expensive machine, is absolutely your friend in this situation.

With the stamp made, I was able to move onto mold production -- everything is more efficient in numbers so throwing the 6 forms, then lubricating them, rolling out 6 fat coils to hold the metal cylinders in place... it is satisfying working in numbers.

I made 5 molds and one for luck. I was telling my husband about the mold production day and realised that my 'one for luck' is such a 'tell' I've lived in Asia. In the West the 'luck' item would be good luck - but I made one more mold than I needed so that the bad luck could go to that mold, like a Japanese carp in a pond -- there to take the bad luck from the home owners - my 6th mold protected the first 5 from having flaws. Anyway -- I made 6, one went wrong, I was okay with that. Moving on...

Throughout this project I've really enjoyed looking out over my work table (& shelves) at a sea of cups -- and found myself taking photos all the time - they just look so good to me & it's sad to see the photos go to waste - just clogging up my dropbox & pushing me over my storage limit so here's a few more to share...

That's it really - shape, colour, volume... and then I set about making them. I think I made about 200 cups (I still need to do a final count for my own learnings) so as to ensure that I could deliver only the best pieces to Synesso. Working to the old business saying 'under promise and over deliver' I gave them a few more than 150, and a few larger cups with the same surface treatment to have around the office for everyone to enjoy. Thinking about it now, what I should have done was made them some dog bowls... Have you visited the Synesso offices?! They have the best collection of woofers in one office I've ever met... all amazingly well behave and friendly. I think with that, I should finish on a living, breathing Fraggle Rock Dog... Phyllis who I really am a little obsessed with.

(Can we have a hashtag #Phylacious!)

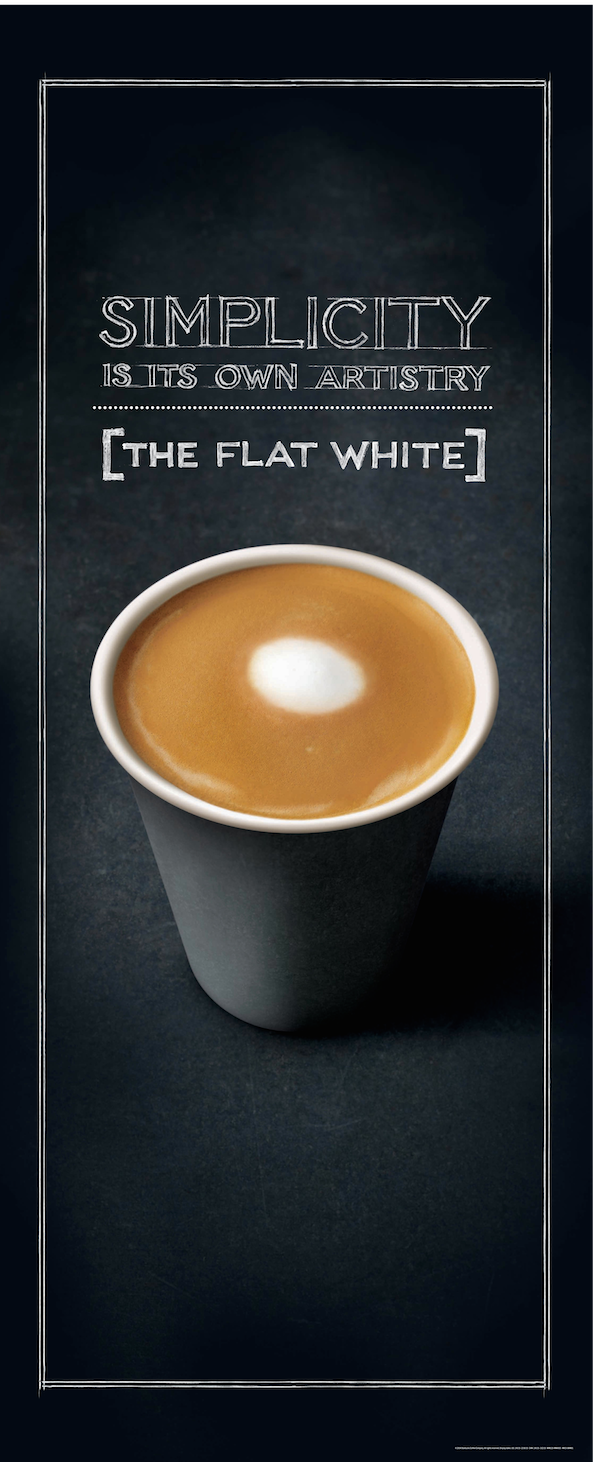

flat white (that's my cup!)

So the Monday after Salad Bowl still in a daze from the late nights (getting home after 1 am two nights in a row) and all the work that went into it… I get an email through via my website.

Hi. My name is Scott and I am a Seattle-based food photographer. I am working on a shoot for Starbucks that requires 4-6 custom coffee mugs (without handles) - produced and delivered by August 26. Please let me know if you are interested and available and I can send further details.

It was August 18th – so the 26th was 8 days away. They came to the studio the next day and so I had 7 days from briefing to delivery. If you don't know clay, this is a very fast turn around - but achievable because lots of things aligned to make this happen in the way that it did:

- they specifically wanted a cup with no handle

my cups don’t have handles! (I've never seen a handle I've like enough to make it mine)

- they wanted it glazed on the inside, and not on the outside

that’s how I glaze my cups, so lots of experience working that way

- they wanted the cups in a slate grey / black

I had started running tests (as you've seen earlier) with the black / grey

- they wanted it white on the inside

yup, that’s how I do my work too

- Lastly, they wanted a satin finish glaze on the inside so it would behave under the photographer’s lights.

which I'd originally thought I'd be doing for all my work - so had that in stock and tested too.

The cherry on top was that the campaign was for a Flat White - & that’s my coffee!! Its how I drank my coffee in Melbourne – and I still try and order the same thing here which is always an effort “a 12oz latte with 2/3rds the normal amount of milk and no foam, please.” This is Seattle, and being specific about your coffee is okay - but even this is taking it a bit too far. I’m thrilled that its going to become a part of American’s vernacular!

The campaign launches today in the US and Canada from what I understand – in every Starbucks. You know that just 13,000 (ish) stores with a picture of my cup in it! I'm don't think I believe in that "15 minutes of fame " thing - but if this is my 15 minutes, I'm thrilled. Thank you universe.

Lastly, I don't think writing about this is complete - without say working with Scott had been a pleasure. He’s been a dream client. He gave me a very specific briefing, was interested in my process so that he could understand what the parameters are that we were working within… and was a champion of my work. He's also a really genuine guy. I couldn't have asked for more.

Oh and final cherry on top of the cherry?! I was paid 4 days after submitting the invoice, and the check was cut on my birthday. I have to say, this project was probably the best birthday present.

keeping an eye on myself

I'm always snapping photos as I go - it really helps me keep track of where I am in the process. It also motivates me, I love seeing these snaps on my camera mix in amongst the other things that I was excited about during the day. (I'm that person that punctuations my conversations in person with a picture "the sky this morning was electric orange".)

From documenting what was loaded in a kiln (how many cups did I make?) to knowing what was on the other side of a piece when it's in a mold and I can't see it -- here's a little sampling from this months' photos:

This set - tells me what's the other side of a piece.

These are all the outside, or the bottom of the pieces you are looking at:

These are kiln loads, and unloads. I love multiples - so when I've set a kiln to fire overnight, seeing these on my phone before I go to sleep almost excites me too much to sleep through the night. The kiln interior shots are useful for me to consider what fits the most pieces in for future efficiency.

Also, Tetris!!

Last but not least - shiny glazed work, fresh and tinkling as it cools, out the kiln. I always document new work before it goes out the door, especially if it is a new design. However before that, and before I give everything its final sanding I like to see what's there - what failed, what split and then indulge myself in a few photos that speak to multiples and production, rather than design. It takes a lot of work to get a table full of ceramics like this - and so I indulge myself. :-)